What exactly are “wearables?”

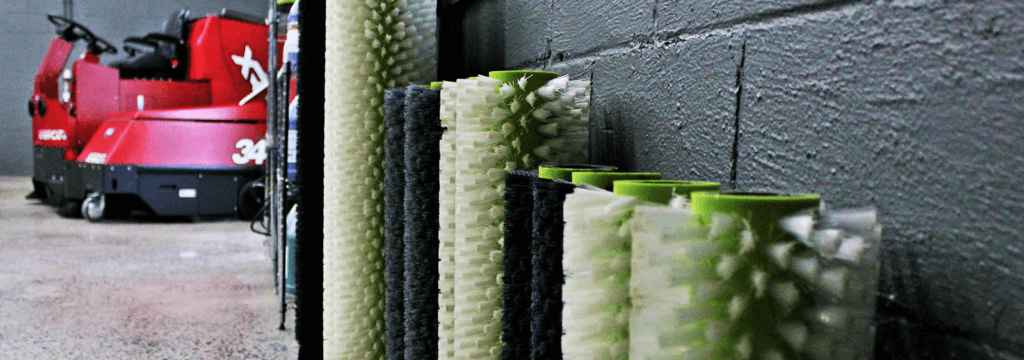

Wearables on your machine include things like brooms, brushes, pads, squeegees, belts, filters, oil, casters, etc. Essentially, any part of the machine that contribute to the operation of your machine and tend to wear out over time. Hence the name! These parts wear down in an effort to protect the integrity and, ultimately, the life span of the major components of your machine (i.e. motors, frame, electronics, tanks).

Wearables on your machine include things like brooms, brushes, pads, squeegees, belts, filters, oil, casters, etc. Essentially, any part of the machine that contribute to the operation of your machine and tend to wear out over time. Hence the name! These parts wear down in an effort to protect the integrity and, ultimately, the life span of the major components of your machine (i.e. motors, frame, electronics, tanks).

These parts are usually able to be replaced at the operator-level and don’t involve extensive disassembly/reassembly of your machine. For most parts, it’s as simple as swapping one part out for another. Kind of like how a pit crew at the Indianapolis 500 replaces the wheels on the Indy Cars. Maybe not quite as epic but the spirit remains the same!

Why should I bother stocking these myself?

Money. Okay, that’s a little vague. What we mean is that spending a little bit now to stock the wearable parts your machine uses is so you can save money down the line. Think about it, your guy or gal is running your machine, maintaining the beauty and sanitation of your facility, effectively cleaning your floors when, all of a suddden, you start noticing your machine is missing a whole lot of dirt on the floor. You inspect the broom and see that, yikes, it’s pretty worn down. Now, since you thought ahead, your operator runs on over to where you store your wearable parts, pops out the old broom, pops in the new one, and gets back to it.

Money. Okay, that’s a little vague. What we mean is that spending a little bit now to stock the wearable parts your machine uses is so you can save money down the line. Think about it, your guy or gal is running your machine, maintaining the beauty and sanitation of your facility, effectively cleaning your floors when, all of a suddden, you start noticing your machine is missing a whole lot of dirt on the floor. You inspect the broom and see that, yikes, it’s pretty worn down. Now, since you thought ahead, your operator runs on over to where you store your wearable parts, pops out the old broom, pops in the new one, and gets back to it.

Same scenario, only this time, you decided against stocking any wearable parts. Your machine is now down until the part(s) you need get delivered or your local service technician shows up to help. That scenario really isn’t an option for some folks and ends up costing you more overall.

Not sure about you, but we get a kick out of doing things ourselves and saving money. To each their own, of course!

Should I still stock these parts if I don’t know how to use them?

Yes! We totally understand that everyone has their respective strengths and weaknesses. So, if your strength is managing a team but you have zero mechanical inclinations, it might seem unnecessary to have these parts on hand because, let’s face it, you really can never seem to find that “phillips flathead” your buddy always asks you to grab.

Yes! We totally understand that everyone has their respective strengths and weaknesses. So, if your strength is managing a team but you have zero mechanical inclinations, it might seem unnecessary to have these parts on hand because, let’s face it, you really can never seem to find that “phillips flathead” your buddy always asks you to grab.

Now this point is more geared towards your machine receiving a little TLC from your local service technician. Since you’re a very respectable and responsible adult, you have a Planned Maintenance schedule for your floor scrubbers & sweepers. Your service technician arrives and finds your machine’s broom is completely worn down and a switch on the control board is toast. The tech makes a note and runs to his van to see if the parts are there.. and, as they suspected, they had the switch on hand, but had no luck on the type of broom your machine has.

The benefit of having those wearable parts on hand is that your tech can head over to your stock and install the new broom, free of charge, and install the switch– effectively restoring your machine’s operational capability and ensuring you can return to delivering quality cleaning results. If you didn’t have that broom, they’d have to either order or pick up a broom to install on your machine, which would cause a second visit to be in order and for your machine to be down for longer. That and costs for these types of scenarios can add up pretty quick!

We can already hear your question, “now, why wouldn’t that service tech have every part he/she might need in their van?” Oh man, we wish we could do that. Problem is… in order to stock every part we’d need for every machine, our service techs would have to use an 18-wheeler to go on every service visit. Think of our service vans as “First-Aid Kits.” We have everything that we need stocked in order to ensure most patients (machines) can get the care they need to remain stable (operational). Usually, these Service Vans that we’ve assembled do the trick and lets your equipment remain at peak running condition after a visit from us (If money was no object, that 18-wheeler service fleet would be pretty awesome to see.. big trucks rolling in just to replace a squeegee would be pretty baller)!

What kind of wearable parts should I usually have on hand?

At the very least, you should have spare squeegees, brushes, and brooms. Those are the most commonly replaced parts on your machine as they are in constant contact with the floor, wearing down. They’re also the most simple to replace and is easily done at the operator-level.

Other great things to have on hand are filters, belts, switches, bumper rollers, casters, etc. Basically, anything that could wear out or break. Much of that depends on the way your operator takes care of your machine. If they’re careless and constantly run into walls, refuse to inspect daily maintenance points, fail to empty the hopper/recovery tank, run over debris that cause problems (pallet wrap, rope, chains, etc.), or anything like that, your wearables will take a beating quicker.

We highly recommend that anyone with any make and model of floor scrubber, sweeper, scrubber/sweeper, street sweeper, hydro excavator, etc. ensure they’re always stocked with common wear items. This is all in an effort to ensure you’re able to accomplish the job at hand without missing a beat and making sure your machine and team experience maximum uptime!

Have questions? Want to learn which parts would be best to stock for your equipment? Let’s talk! We’d love to help!